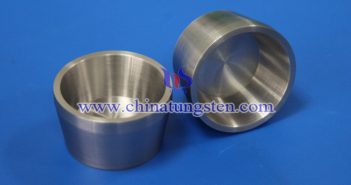

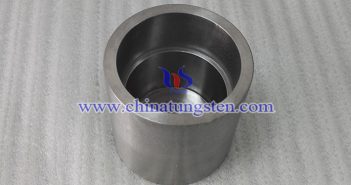

In some special high-temperature atmospheres or melt environments, tungsten crucibles still face a certain degree of corrosion problems. Corrosion not only affects the service life of the crucible, but can also contaminate the material being treated and reduce product quality. Therefore, improving the corrosion resistance of the crucible is the key to improving its comprehensive performance and prolonging the service life. In this paper, the corrosion mechanism, influencing factors and main improvement methods are systematically analyzed and discussed. 1. The…