The production of tungsten alloy collimators combines material characteristics with manufacturing technologies, with mainstream methods including powder metallurgy, precision machining, powder injection molding, and others. These production methods cater to products with varying structural complexity and precision requirements, collectively ensuring the collimators' efficiency and stability in radiation control.

Powder metallurgy is the foundational process for producing tungsten alloy collimators, suitable for batch manufacturing of small to medium-sized, structurally regular products. The process involves three stages: raw material mixing, compaction molding, and sintering densification. High-purity tungsten powder is mixed with metal powders like nickel and iron in specific proportions and ball-milled under inert gas protection. The mixed powder is then loaded into a mold, pressed into a green compact using a hydraulic press, and heated in a hydrogen-protected furnace to remove impurities, followed by high-temperature sintering. This allows tungsten particles to diffuse and weld into a dense structure, achieving a high density level. This method offers high material utilization, low cost, and the ability to adjust parameters for performance control, meeting the needs of basic collimator designs.

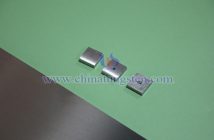

Precision machining is a key technique for achieving complex structures and high precision in collimators, often used in conjunction with powder metallurgy. For sintered tungsten alloy blanks, processes such as external milling and internal drilling are performed using CNC machining centers to refine the shape and accuracy.

Powder injection molding is suitable for manufacturing tungsten alloy collimators with relatively complex structures, such as those with curved channels or thin-walled grids. The process includes feedstock preparation, injection molding, debinding, and sintering. Initially, tungsten powder is mixed with a binder in specific proportions, and the feedstock is injected into a mold to form a green compact. After debinding, the compact is sintered in a furnace to achieve densification. This method boasts high material utilization and good product consistency.

Additionally, 3D printing technology can be employed for specific scenario needs. Using selective laser melting, this technique layer-by-layer builds tungsten alloy collimators with internal hollow structures from mixed powders. It is suitable for producing small-sized products but comes with higher costs.

Regardless of the method used, key parameters must be controlled during production: raw material purity affects the final shielding performance, sintering temperature impacts alloy density, and machining precision influences ray control effectiveness.