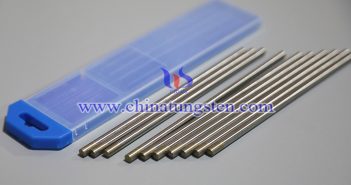

Tungsten inert gas welding (TIG) and plasma welding, the choice of electrode material plays a decisive role in the welding quality. With the widespread application of environmentally friendly materials, lanthanum tungsten electrode has gradually become an important choice in the welding industry. In addition to the material properties themselves, the selection of size is also one of the key factors that determine the success or failure of welding. The diameter and length of the electrode are not only related to…